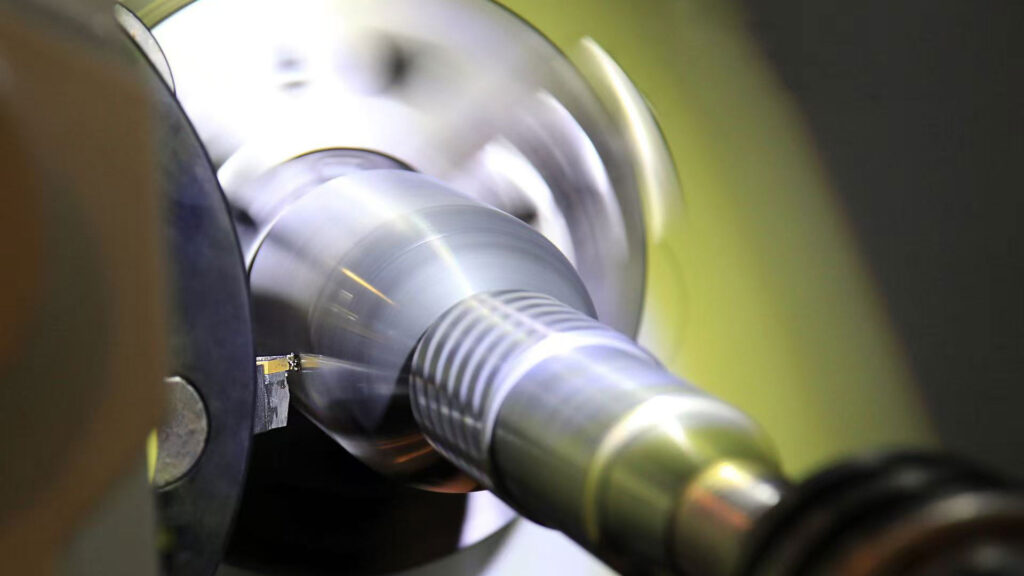

CNC Turning Parts: Everything You Need to Know

CNC turning is a foundation process in modern subtractive manufacturing, enabling cylindrical and axis-symmetric parts to be produced with high precision, consistency, and efficiency. By rotating the workpiece at a controlled speed while a programmed cutting tool removes material, precision CNC turning centers can often hold ±0.02 mm to ±0.01 mm on select critical turned […]

Non-Negotiable Precision: Why CNC Machining is Essential for High-Accuracy Robotic Components

The global robotics and automation industry is currently undergoing a renaissance, driven by demands for greater speed, heavier payloads, and absolute accuracy across manufacturing, logistics, and surgery. Yet, the performance of the most advanced robotic systems ultimately relies on the quality of their most fundamental structural elements. In this high-stakes environment, CNC machining is not […]

A Comprehensive Guide to Splined Shaft Machining

Splined shafts are essential for high-precision torque transfer—but their design and machining are anything but simple. Splined shafts are cylindrical mechanical components with ridged teeth (splines) that transmit torque between connected parts. They’re used across aerospace, automotive, robotics, and industrial machinery applications, and demand tight tolerances and precision fitment for flawless operation. In this guide, […]

A Complete Guide to ISO 2768 CNC Machining Tolerance Standards

In CNC machining, precision is everything—but not every feature needs micrometer-level tolerances. When dimensions don’t have specific callouts, ISO 2768 offers a reliable, global standard that ensures functionality without overcomplicating your drawings. ISO 2768 defines general tolerances for linear, angular, and geometric features in the absence of explicitly stated tolerances. It’s essential for engineers and […]

From Firearms to Warships: CNC Machining Applications in the Defense Industry

Even minor part failures can compromise entire missions or cost lives. CNC machining delivers the precision, strength, and compliance required for defense-grade components—across small arms, aircraft, naval vessels, and beyond. This guide explores why CNC machining is essential in defense, examines key applications by domain, outlines material and tolerance requirements, and explains why Onlyindustries is […]

Custom Shaft Manufacturing Explained: Types, Processes, and Best Practices

Shaft failure often stems from overlooked specs and misaligned process choices. A shaft is a precision component that transmits torque, supports rotating parts, maintains alignment, and absorbs bending stress—essential in engines, robots, and industrial machines. In this guide, I’ll walk through shaft types, manufacturing processes, materials, tolerances, surface finishes, sourcing tips, and why Onlyindustries is […]

Maximize Component Performance with DLC Coating

Is wear and friction shortening your components’ lifespan and costing you in downtime? DLC coating delivers diamond-like hardness and ultra-low friction in a thin layer—enhancing reliability, longevity, and performance in demanding applications. In this guide, I’ll explain how DLC works, explore coating types and their benefits, and share how you can apply best practices to […]

Anodized Aluminum Colors: How to Achieve Ideal and Consistent Color Matches

Inconsistent anodized colors can disrupt your product aesthetics, lead to rejections, and damage your brand image. But there’s a way to take control. Anodized aluminum colors are created through a delicate balance of alloy choice, surface preparation, anodizing process control, and dye chemistry. Achieving consistent results across batches requires more than guesswork—it requires discipline, standards, […]

Top Metals Essential for Medical Device Applications

Choosing the right metal for a medical device impacts biocompatibility, durability, and regulatory approval. This guide examines the top metals used in medical devices, highlighting their properties, applications, and critical decision factors. Understanding each metal’s strengths ensures your device performs reliably and meets compliance standards. Why Metals Are Preferred in Medical Devices? Many manufacturers struggle […]

Tolerance and Allowance: How They Differ in Engineering Applications

Ever had parts that fit improperly or broke unexpectedly? I’ve felt that frustration. The root cause often lies in confusing tolerance with allowance—and that tiny mix-up can derail projects and hike costs. Tolerance defines manufacturable variation; allowance defines intentional fit. They work together to ensure parts meet design intent and assemble reliably. This post explains […]