Stamping Parts

Stamping Parts

Our stamping parts range from laser cutting parts and bending parts to sheet metal parts, with flexible service options. On top of that, if you need assembly parts service, we can provide that for you as well. Contact us today for a quote.

- 20-day delivery on laser cutting parts

- High ROI, progressive dies

- Custom surface treatments available

Table Of Contents For This Page

Diving into every detail of stamping parts can be intricate, so we’ve assembled extensive information on this page for your ease. To help you promptly find the specific details you need, we’ve created a content directory that will take you straight to the relevant sections when clicked.

Assorted Applications

Stamping is a widely-used manufacturing process that supports various industries by efficiently creating high-quality, complex parts.

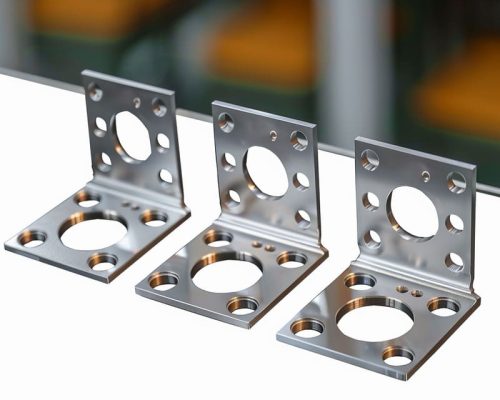

Stamping Parts Product Gallery

Explore our specialized stamping solutions crafted for various industrial applications.

Common Materials Used in Stamping Parts

Comprehensive list of materials commonly used in stamping applications, detailing grades, chemical compositions, and specific uses.

Carbon Steel

| Carbon Steel | Characteristics | Specific Application Products |

|---|---|---|

| SAE 1008 | High ductility, good formability, excellent weldability | Automotive body panels, brackets, enclosures, light-duty frames |

| SAE 1010 | Similar to SAE 1008 with slightly higher carbon content, offering improved strength | Car frames, structural components, general stamping applications |

| SAE 1020 | Good balance of strength and ductility, excellent weldability | Light-duty gears, machinery components, automotive parts, fasteners |

| SAE 1040 | Higher strength and hardness than low carbon steels, good wear resistance | Engine components, axles, heavy-duty gears, structural beams |

| SAE 1050 | High hardness and strength, less ductile than lower carbon steels | Springs, high-strength fasteners, cutting tools, agricultural machinery parts |

| SAE 1070 | Very high strength and hardness, excellent wear resistance, less ductile | High-strength springs, cutting tools, wear-resistant parts |

| ASTM A36 | Common structural steel, good weldability and formability, widely available | Structural components, frames, brackets, general construction applications |

Stainless Steel

| Stainless Steel | Characteristics | Specific Application Products |

|---|---|---|

| AISI 304 | Excellent corrosion resistance, good formability, weldability, non-magnetic in annealed condition | Kitchen equipment, food processing machinery, automotive trim, sinks, and tubing |

| AISI 316 | Superior corrosion resistance, especially against chlorides and acidic environments, good formability | Marine applications, chemical processing equipment, medical devices, heat exchangers |

| AISI 430 | Good corrosion resistance, particularly against nitric acid, good formability, magnetic | Appliance components, automotive trim, kitchen utensils, architectural applications |

| AISI 410 | High strength and hardness, good corrosion resistance, good wear resistance, magnetic | Cutlery, surgical instruments, fasteners, valves, and pump parts |

| AISI 420 | Higher carbon content for increased hardness and wear resistance, good corrosion resistance, magnetic | Surgical instruments, cutting tools, needle valves, and shear blades |

| AISI 301 | High strength, excellent corrosion resistance, good ductility and formability, high fatigue strength | Springs, clamps, automotive trim, and flexible bellows |

| AISI 201 | Economical alternative with good formability and corrosion resistance, high work hardening rate | Kitchen equipment, sinks, cooking utensils, and automotive trim |

| AISI 409 | Good high-temperature corrosion resistance, economical, weldability, magnetic | Automotive exhaust systems, heat exchangers, and furnace components |

| AISI 439 | Excellent corrosion resistance, good formability, weldability, magnetic | Automotive exhaust systems, hot water tanks, and solar water heaters |

Aluminum

| Aluminum | Characteristics | Specific Application Products |

|---|---|---|

| 1100 | High ductility, excellent corrosion resistance, good formability, pure aluminum | Decorative trim, kitchen utensils, heat exchangers, reflective surfaces |

| 3003 | Good corrosion resistance, excellent workability, moderate strength, widely used | Cooking utensils, chemical equipment, storage tanks, HVAC components |

| 5052 | High fatigue strength, excellent corrosion resistance, good formability, weldable | Fuel tanks, marine applications, pressure vessels, automotive components |

| 6061 | High strength, good corrosion resistance, excellent machinability, heat-treatable | Structural components, aerospace frames, automotive parts, bicycle frames, piping |

| 7075 | Very high strength, good fatigue resistance, less corrosion resistance, machinable, heat-treatable | Aerospace components, high-stress applications, sporting goods |

| 3004 | Higher strength than 3003, good formability, good corrosion resistance | Beverage cans, cooking utensils, storage tanks, chemical handling equipment |

| 6063 | Good formability, excellent corrosion resistance, good mechanical properties, easily extruded | Architectural applications, window frames, irrigation tubing, decorative trim |

| 5083 | Excellent corrosion resistance, particularly in marine environments, high strength | Marine applications, pressure vessels, cryogenic equipment |

| 1050 | Similar to 1100 with slightly lower strength, excellent corrosion resistance, good formability | Chemical and food processing equipment, lamp reflectors, nameplates, fan blades |

| 1200 | Similar to 1100 with high corrosion resistance, excellent workability, and moderate strength | Electrical conductors, heat exchangers, architectural flashings, chemical equipment |

| 1350 | High electrical conductivity, excellent corrosion resistance, good formability | Electrical wiring and conductors, bus bars, transformer windings, power grid cables |

| 1145 | Excellent corrosion resistance, high purity aluminum, good formability | Heat exchangers, packaging foil, chemical storage, food and pharmaceutical packaging |

Bronze

| Bronze Grade | Characteristics | Specific Application Products |

|---|---|---|

| C51000 (Phosphor Bronze) | Good strength, excellent fatigue resistance, good corrosion resistance, low friction | Bearings, springs, bushings, electrical connectors, marine hardware, fasteners |

| C54400 (Beryllium Bronze) | High strength, good conductivity, excellent wear resistance, good fatigue resistance | Springs, non-sparking tools, electrical connectors, precision instruments, diaphragms |

| C93200 (Bearing Bronze) | Excellent wear resistance, good load-bearing properties, good machinability, good corrosion resistance | Bearings, bushings, thrust washers, pump components, gears |

| C95400 (Aluminum Bronze) | High strength, excellent corrosion resistance, good wear and fatigue resistance | Heavy-duty bushings, gears, pump parts, marine hardware, hydraulic components |

| C90300 (Tin Bronze) | Good corrosion resistance, good wear resistance, good machinability | Bearings, bushings, gears, marine components, pump parts |

| C95500 (Nickel Aluminum Bronze) | High strength, excellent corrosion resistance, good wear resistance, non-sparking | Marine hardware, ship propellers, heavy-duty bearings, valve components, pump shafts |

| C90700 (High-Tin Bronze) | Good strength, excellent corrosion resistance, good wear resistance, good machinability | Gears, worm gears, bushings, bearings, heavy-duty machinery components |

Nickel Alloy

| Nickel Alloy | Characteristics | Specific Application Products |

|---|---|---|

| Monel 400 | Excellent corrosion resistance, good weldability, high strength, good ductility | Marine engineering, chemical processing equipment, pump and valve components, fasteners, springs |

| Inconel 600 | High strength, excellent oxidation and corrosion resistance at high temperatures, good weldability | Heat exchangers, furnace components, chemical processing equipment, gas turbine components |

| Inconel 625 | Excellent fatigue and thermal-fatigue resistance, oxidation and corrosion resistant, good weldability | Aerospace components, chemical processing equipment, marine applications, nuclear reactors |

| Hastelloy C276 | Excellent corrosion resistance in a wide range of severe environments, good weldability | Chemical processing, pollution control equipment, marine engineering, pulp and paper industry |

| Nickel 200 | High electrical and thermal conductivity, good corrosion resistance, good ductility | Electrical components, food processing equipment, chemical and petrochemical processing |

| Incoloy 800 | High strength, excellent resistance to oxidation and carburization at high temperatures | Heat exchangers, furnace parts, chemical and petrochemical processing equipment |

| Alloy 20 | Excellent corrosion resistance, particularly to sulfuric acid, good mechanical properties | Chemical and pharmaceutical processing, food processing, synthetic rubber manufacturing |

| Nichrome (80/20) | High electrical resistance, good oxidation resistance at high temperatures | Heating elements, resistance wire, electrical resistors, laboratory crucibles |

Titanium

| Titanium Grade | Characteristics | Specific Application Products |

|---|---|---|

| Grade 1 (Commercially Pure Titanium) | Excellent corrosion resistance, high ductility, good formability, low strength | Chemical processing equipment, marine applications, medical implants, heat exchangers |

| Grade 2 (Commercially Pure Titanium) | Excellent corrosion resistance, good balance of strength and ductility, widely used | Pressure vessels, marine components, aircraft structures, chemical processing equipment |

| Grade 3 (Commercially Pure Titanium) | Good strength, excellent corrosion resistance, moderate ductility | Aerospace structures, chemical processing, marine environments |

| Grade 4 (Commercially Pure Titanium) | Highest strength of the commercially pure grades, excellent corrosion resistance, moderate formability | Aerospace components, surgical implants, marine and industrial applications |

| Grade 5 (Ti-6Al-4V) | High strength, excellent corrosion resistance, good weldability, most commonly used alloy | Aerospace fasteners and components, medical implants, high-performance automotive parts, sports equipment |

| Grade 7 (Ti-0.2Pd) | Similar to Grade 2 with added palladium for enhanced corrosion resistance, especially in reducing acids | Chemical processing, industrial applications exposed to severe corrosive environments |

| Grade 9 (Ti-3Al-2.5V) | Moderate strength, excellent corrosion resistance, good formability, better cold-formability than Grade 5 | Aircraft tubing, sports equipment, marine applications, medical devices |

| Grade 12 (Ti-0.3Mo-0.8Ni) | Excellent corrosion resistance, especially to crevice corrosion, good strength, good formability | Chemical processing, marine and industrial applications exposed to high-temperature environments |

Plastic and Composite

| Material Grade | Characteristics | Specific Application Products |

|---|---|---|

| Polycarbonate (PC) | High impact resistance, transparent, good dimensional stability, high temperature resistance | Protective gear, lenses, electronic housings, safety helmets, automotive components |

| Polyethylene (PE) | Excellent chemical resistance, low cost, high impact resistance, good flexibility | Bottles, containers, piping systems, packaging, cutting boards, marine components |

| High-Density Polyethylene (HDPE) | Higher strength and stiffness compared to standard PE, good chemical resistance, low moisture absorption | Fuel tanks, water pipes, food storage containers, playground equipment, automotive fuel tanks |

| Polypropylene (PP) | High chemical resistance, good fatigue resistance, lightweight, excellent dielectric properties | Automotive components, medical devices, consumer goods, packaging, living hinges |

| Polyvinyl Chloride (PVC) | High strength, excellent chemical and fire resistance, versatile, can be rigid or flexible | Pipes, cable insulation, medical tubing, window frames, flooring |

| Acrylonitrile Butadiene Styrene (ABS) | High impact resistance, good machinability, easy to mold, good strength | Automotive trim, consumer electronics, toys, protective gear, enclosures |

| Nylon (PA) | High strength and toughness, excellent wear resistance, good chemical resistance, self-lubricating properties | Gears, bearings, automotive parts, industrial machine components, electrical insulators |

| Fiber-Reinforced Plastics (FRP) | High strength-to-weight ratio, excellent corrosion resistance, customizable properties | Aircraft panels, boat hulls, structural components, industrial equipment |

| Carbon Fiber Composites | Very high strength-to-weight ratio, excellent stiffness, good fatigue resistance, low thermal expansion | Aerospace components, high-performance sporting goods, automotive parts, prosthetics |

| Glass Fiber-Reinforced Plastics (GFRP) | Good strength-to-weight ratio, high corrosion resistance, electrical insulating properties | Electrical enclosures, automotive parts, marine components, construction materials |

| Polyoxymethylene (POM or Acetal) | High stiffness, low friction, excellent dimensional stability, good wear resistance | Precision gears, bearings, automotive components, conveyor belts, fasteners |

| Polyetheretherketone (PEEK) | High strength, excellent chemical resistance, high-temperature resistance, good wear resistance | Aerospace components, medical implants, high-performance automotive parts, semiconductor machinery |

Surface Treatment of Stamping Parts

Surface treatment of stamped parts plays a key role in enhancing the appearance, durability, and overall performance of the final products.

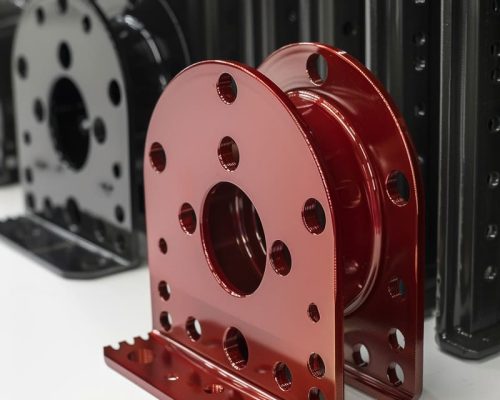

Powder Coating

Powder coating of stamped parts helps performance and aesthetics by applying a dry powder composed of resin, pigments, and additives. Cured under heat, it forms a durable, corrosion-resistant finish that prevents rust and wear. Offering various colors and finishes, it improves appearance while being environmentally friendly, emitting minimal VOCs. This makes powder coating ideal for industries needing durable, reliable, and compliant stamped parts.

Anodizing

Anodizing of stamped parts boosts functionality by enhancing corrosion resistance and surface hardness, offering protection against moisture and chemicals. This electrochemical process forms a durable oxide layer, improving wear resistance and longevity. It also provides various color finishes, enhancing aesthetic appeal while maintaining structural integrity. Additionally, anodizing is eco-friendly, producing minimal waste, making it a sustainable choice for performance and appearance enhancement.

Electroplating

Stamped parts are plated by an electrochemical process with a thin metallic coating, usually made of nickel, chromium or zinc, which provides excellent corrosion resistance and protects the parts from rust and degradation due to moisture, chemicals and environmental factors. In addition, plating improves wear resistance and reduces the risk of scratches and mechanical damage. The process also enhances electrical conductivity, making it ideal for electronic components.

Painting

Painting of stamped parts involves applying a liquid paint coating to the surface of the parts, providing a barrier against corrosion, moisture, and environmental damage. Painting offers a wide range of color options and finishes, allowing customization to meet specific design requirements. Additionally, painted surfaces are easier to clean and maintain, ensuring the stamped parts remain visually appealing and functional over time. This surface treatment is crucial for industries seeking both aesthetic and protective benefits for their stamped components.

Passivation

Passivation of stamped parts, which chemical treatment involves immersing the parts in an acid solution to remove contaminants and free iron from the surface, creating a passive oxide layer that protects against rust and corrosion. Passivation is particularly effective for stainless steel parts, improving their longevity and performance in harsh environments. Additionally, this process enhances the overall cleanliness of the parts, making them suitable for critical applications in industries such as medical, aerospace, and food processing, where maintaining high levels of hygiene and durability is essential.

Black Oxide

Black oxide treatment of stamped parts refers to immersing the parts in a series of chemical baths, converting the surface into a black oxide finish. The resulting layer provides a mild corrosion resistance, reduces light reflection, and improves lubricity, making assembly easier. Black oxide is also beneficial for reducing glare and improving the aesthetic appeal of parts. Commonly used in the automotive, aerospace, and tooling industries, this treatment is valued for its cost-effectiveness and the added layer of protection it offers to stamped components.

Phosphating

Phosphating of stamped parts relates immersing the parts in a phosphate solution, which chemically reacts with the metal surface to form a crystalline phosphate coating. This coating provides excellent corrosion resistance and enhances paint adhesion, making it an ideal pre-treatment for painted or coated parts. Additionally, phosphating reduces friction and wear, extending the lifespan of the parts. Phosphating is valued for its ability to improve the durability, performance, and overall quality of stamped components.

Pickling

Pickling of stamped parts engages immersing the parts in an acid solution to remove scale, rust, and other surface impurities. This process cleans the metal surface thoroughly, ensuring better adhesion for subsequent coatings or treatments. Pickling enhances the overall quality and appearance of the parts, making them suitable for further processing such as painting, plating, or welding.

Nickel Plating

Nickel plating of stamped parts concerns electroplating a thin layer of nickel onto the surface of the parts. This process enhances the parts’ corrosion resistance, wear resistance, and overall durability. The nickel coating provides a smooth, hard surface that protects against environmental factors such as moisture and chemicals, preventing rust and degradation. Additionally, nickel plating improves the aesthetic appeal of the parts with a bright, shiny finish. This treatment is commonly used in automotive, electronics, and industrial applications, where both functional and decorative benefits are required.

Typical Tolerances for Stamping Parts

Tolerances are crucial in stamping parts as they ensure the parts fit together correctly and function as intended.

| Dimension Type | Typical Tolerance Range | Application Examples | |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm to ±0.1 mm | General stamped parts, automotive components | |

| Hole Diameter | ±0.05 mm to ±0.1 mm | Electronics enclosures, precision machinery parts | |

| Flatness | 0.1 mm per 100 mm | Aerospace components, medical device housings | |

| Angularity | ±0.5° to ±1.0° | Structural brackets, support frames | |

| Bend Radius | ±0.2 mm to ±0.5 mm | Sheet metal parts, construction elements | |

| Profile | ±0.1 mm | Automotive body panels, decorative trims | |

| Perpendicularity | ±0.05 mm to ±0.1 mm | Connector housings, machine frames | |

| Positional Tolerance | ±0.1 mm to ±0.2 mm | Circuit board components, precision electronic parts | |

| Surface Finish | Ra 0.8 µm to Ra 1.6 µm | Visible parts, high-contact surfaces |

Key Considerations for Tolerances:

- Material Type: Different materials can have different tolerances based on their properties.

- Part Complexity: More complex parts might require tighter tolerances.

- Application Requirements: Specific industry standards may dictate the necessary tolerances.

- Tooling and Equipment: The precision of the stamping equipment can affect achievable tolerances.

Factors Influencing Tolerances in Stamping:

- Material Thickness: Thicker materials may require larger tolerances.

- Tool Wear: Over time, tooling can wear out, affecting tolerances.

- Process Control: Consistent process control helps maintain tight tolerances.

- Inspection Methods: Advanced inspection methods can ensure tighter tolerances.

Examples of Tolerances in Specific Applications

Automotive:

- Car Frames: Linear dimensions ±0.1 mm

- Brackets: Hole diameter ±0.05 mm

- Exhaust Parts: Bend radius ±0.5 mm

Electronics:

- Enclosures: Positional tolerance ±0.1 mm

- Circuit Boards: Hole diameter ±0.05 mm

- Cooling Fins: Flatness 0.1 mm per 100 mm

Aerospace:

- Fuselage Components: Flatness 0.1 mm per 100 mm

- Engine Components: Angularity ±0.5°

- Brackets: Perpendicularity ±0.05 mm

Medical Devices:

- Surgical Instruments: Surface finish Ra 0.8 µm

- Imaging Device Frames: Positional tolerance ±0.1 mm

- Device Enclosures: Linear dimensions ±0.05 mm

Understanding Stamping Parts: A Complete Guide

01

Material Costs

Material costs depend on the type and grade of the material used for stamping. Common materials include steel, aluminum, and copper, with specific grades like SAE 1008 steel or 6061 aluminum. The cost is influenced by market prices, material thickness, and the amount of material required per part.

- Example:

- Steel: $0.50 per pound

- Aluminum: $1.50 per pound

- Copper: $3.00 per pound

02

Tooling Costs

Tooling costs are significant in stamping operations, including the design, production, and maintenance of dies and molds. These are usually one-time costs but can be high, especially for complex parts.

- Example:

- Simple die: $5,000 – $10,000

- Complex die: $20,000 – $50,000

03

Labor Costs

Labor costs cover the wages of operators and other personnel involved in the stamping process. This includes setup, operation, and maintenance of stamping machines, as well as quality control and inspection.

- Example:

- Operator wage: $20 – $30 per hour

- Setup and maintenance: $50 – $100 per hour

04

Overhead Costs

Overhead costs include indirect expenses such as utilities, equipment depreciation, facility rent, and administrative expenses. These costs are often allocated based on machine hours or production volume.

- Example:

- Utilities: $1,000 per month

- Depreciation: $500 per month

- Rent: $2,000 per month

05

Additional Processing Costs

Additional processing costs may involve surface treatments, assembly, packaging, and shipping. Surface treatments like powder coating, anodizing, or plating add to the total cost.

- Example:

- Powder coating: $0.10 – $0.30 per part

- Anodizing: $0.20 – $0.50 per part

- Nickel plating: $0.30 – $0.70 per part

Manufacturing Process & Duration Estimation

Starting our journey to boost your industrial capabilities with precision forging products signifies the onset of a thorough and professional partnership. Here’s a detailed guide through each step of the process, designed with your needs and perspective in mind.

Step 1: Stamping Products Required in Detail (3-7 days)

Grasping Your Requirements: The first step involves a comprehensive consultation to understand your specific requirements, including part dimensions, material type, and any custom features. Our team works closely with you to ensure every detail of the stamped product is tailored to meet your specifications, aligning with your operational needs and industry standards.

Step 2: Sampling (laser cutting parts:15 days while mold:40 days)

Making Your Specifications a Reality: Upon confirming the product details, we proceed with proofing, creating a stamped sample that aligns with your specified requirements. This phase is crucial for you to inspect and evaluate the product, ensuring it meets your expectations for quality, functionality, and design.

Step 3: Settle the Invoice (within 1 day)

Securing Your Order: With the sample approved, a 50% for laser cutting parts or 100% payment for mold initiate the transition from planning to production. These payments are a standard practice, securing your orders in our production schedule and enabling us to allocate the necessary resources and materials to fulfill your stamping request.

Step 4: Bulk production (Laser cutting parts: 20 days while mold: 40 - 50 days)

Constructing Your Solution: With your deposit received, bulk production begins. Our expert engineers and technicians use advanced manufacturing methods to create your stamped parts, ensuring strict adherence to agreed specifications. We maintain open communication throughout this phase, keeping you updated on the progress of your order.

Step 5: Quality Assurance Review (1-2 days)

Upholding Excellence: Before shipment from our facility, each stamped product is subjected to a rigorous quality inspection. This thorough evaluation checks material integrity, dimensional accuracy, structural strength, and adherence to specifications. Our dedication to quality guarantees that the products you receive are ready to perform with precision and reliability in their applications.

Step 6: Arrangement of shipment

Global Logistics Management: Following the completion of manufacturing and quality assurance, we arrange sea transportation for your stamped parts order. We handle the intricacies of international shipping, selecting only trusted carriers for safe and timely delivery to your specified port. Our logistics team takes care of all aspects, from documentation to customs clearance, ensuring a smooth and stress-free process for you.

Upgrade Your Production Standards Now !

Take advantage of the quality and reliability of our stamped products; call us today to improve your manufacturing capabilities.

A Brief Self-Nomination, Why Choose Onlyindustries?

Shape the future of your business with stamping parts built for precision and dependability. Trust in our expert craftsmanship to raise your industrial performance to new heights.

- Industrial components are ISO9001:2015, REACH, and TUV certified to ensure top quality.

- Professional sales and engineers will quick response within 12 hours of your first inquiry.

- You will save 20% cost as we have better system and streamline management expenses.

- 12 years in the business, committed to industrial solutions.

- We invest in continuous learning to maintain our competitive edge.

- Your peace of mind is secured through reliable after-sales support for industrial parts and components.

Superior Service: Addressing Your Stamping Parts Needs with Expertise

Focus on diligently address each and every concern our customers may have.

Working closely with customers during the design phase to ensure their specific requirements are met, offering engineering support and design optimization and adapting our production processes to accommodate custom orders, small batch runs, and prototyping needs.

Assigning dedicated account managers to each customer, providing personalized support and ensuring smooth communication and Offering multilingual support to bridge language barriers and enhance understanding, making it easier for customers to communicate their needs.

Implementing a stringent quality assurance process, including first article inspections, in-process monitoring, and final product testing, ensures every part meets the specified standards, and providing detailed inspection reports with each shipment gives customers confidence in the quality and consistency of the parts received.

Offering a real-time order tracking system that allows customers to monitor the status of their orders from production to delivery, and providing guaranteed lead times and ensuring adherence to delivery schedules to help customers plan their production processes more effectively.

The FAQs About Stamping Parts

Consider using a progressive die when you need high-volume production of complex parts with multiple features, such as holes, bends, and cutouts, in a single, continuous process. For example, progressive dies are ideal for manufacturing automotive components and electrical connectors efficiently, reducing production time and costs by combining several stamping operations into one die setup.

For custom metal stamping parts, the two biggest factors affecting the price are material type and tolerance of part design.

1. Material. We generally choose equivalent or similar alternative materials to obtain cheaper raw materials.

2. Tolerance of part design, we can suggest customers to modify the design to reduce tolerance requirements or the need for secondary processing.

Common issues with stamped parts include burrs, dimensional inaccuracies, and surface defects. We address these by implementing strict quality control measures, such as precision tooling maintenance and regular inspections. For example, burrs are minimized through proper die clearance adjustments, and dimensional inaccuracies are corrected by calibrating our equipment regularly. Surface defects are reduced by using high-quality materials and thorough inspections at each production stage.

Yes, we offer environmentally friendly surface treatments such as powder coating and passivation. For example, powder coating produces minimal volatile organic compounds (VOCs) and provides a durable, attractive finish. Passivation enhances the corrosion resistance of stainless steel without harmful chemicals, making it a sustainable choice for protecting and finishing stamped parts.

The typical process flow for manufacturing stamped parts includes several key steps: design and engineering, tooling and die creation, material selection and preparation, stamping, and finishing. For example, the process begins with designing the part and creating the die, followed by selecting the appropriate material, performing the stamping operation, and then applying any necessary surface treatments or finishes.

The cost of stamped parts is influenced by several factors, including material choice, tooling costs, labor costs, production volume, and additional processing or surface treatments. For example, using a high-grade stainless steel will increase material costs, while complex designs requiring intricate tooling will also raise the overall expense. Higher production volumes typically reduce the per-unit cost.

The process involves reviewing and agreeing on the detailed quote provided. For example, we will discuss all additional costs with the customer, ensure they understand the expenses, and get their approval before proceeding with the project.

Choosing the right surface treatment depends on your application’s specific requirements, such as corrosion resistance, wear resistance, aesthetic appeal, and environmental conditions. For example, if corrosion resistance is a priority, consider zinc plating or anodizing. For aesthetic purposes, powder coating offers a variety of colors and finishes. Evaluate your needs to select the best treatment.

Tooling longevity is maintained through regular maintenance, precision adjustments, and proper storage. For example, we conduct routine inspections to identify wear and tear, perform necessary sharpening or replacement of tool components, and store tooling in controlled environments to prevent damage. This ensures consistent quality and extends the life of the tools.

We handle customer complaints and quality issues through a structured process that includes prompt investigation, root cause analysis, and corrective actions. For example, if a customer reports a dimensional inaccuracy, we immediately review the production records, inspect the remaining stock, and identify the cause. We then implement solutions such as tooling adjustments or process changes to prevent recurrence and ensure customer satisfaction.

Yes, we provide extensive design and engineering support for custom projects. Our team helps optimize designs for manufacturability, selects appropriate materials, and ensures cost efficiency. For example, if you need a custom bracket with specific dimensions and load-bearing requirements, we can collaborate to refine the design and ensure it meets your exact needs and industry standards.

Our tolerances and precision levels for stamped parts typically range from ±0.05 mm to ±0.1 mm, depending on the part's complexity and material. For example, simple flat parts may have a tolerance of ±0.1 mm, while intricate components requiring higher accuracy can achieve tolerances as tight as ±0.05 mm. This ensures that parts fit and function as intended in their applications.

Customer feedback is crucial in addressing quality issues as it helps us understand the problem from the user’s perspective. For example, we encourage customers to report any issues they encounter and provide detailed information, which we use to improve our processes and products.

Our stamped parts are used in a variety of industries, including automotive, aerospace, electronics, medical, industrial machinery, consumer products, construction, and energy. For example, in the automotive industry, our stamped parts are used for body panels and engine components, while in the electronics industry, they are used for enclosures and connectors.

Tooling is crucial in the stamping process because it ensures precision, efficiency, and consistency in producing parts. For example, high-quality dies and molds are essential for achieving accurate dimensions and shapes, reducing material waste, and increasing production speed. Properly designed and maintained tooling minimizes defects and downtime, leading to cost-effective and reliable manufacturing of stamped parts.

We use several types of dies in our stamping operations, including progressive dies, compound dies, and transfer dies. For example, progressive dies are used for high-volume production with multiple operations in a single stroke, compound dies perform multiple operations simultaneously in one station, and transfer dies move parts through a series of stations for complex shapes. Each type is selected based on the specific requirements of the part being produced.

To get a quote for your stamping project, provide us with detailed information, including part specifications, material requirements, production volume, and any additional processing or surface treatments needed. For example, you can send us your CAD drawings or detailed sketches, specify the material type like stainless steel or aluminum, and indicate the quantity required. This information helps us deliver an accurate and competitive quote.

When designing stamped parts, consider material type, thickness, part complexity, and tolerances. For example, choose a material that balances strength and formability, ensure the thickness is consistent for uniform stamping, and avoid overly complex shapes that might complicate the tooling process. Additionally, specify realistic tolerances to ensure manufacturability and cost-effectiveness.

We ensure the quality of our stamped parts through rigorous quality control measures, including first article inspections, in-process inspections, and final inspections. For example, we use precision measuring instruments to check dimensions, surface finishes, and material properties at various stages of production. This systematic approach helps us maintain high standards and deliver parts that meet customer specifications consistently.

Choosing the right material for your stamped parts depends on factors like strength, corrosion resistance, conductivity, and cost. For example, stainless steel is ideal for parts needing high corrosion resistance, while aluminum is preferred for lightweight applications. Assess the specific requirements of your application, such as environmental conditions and mechanical loads, to select the most suitable material.

(2024) In-Depth Guide to Understanding Stamping Parts

Boost the effectiveness of your manufacturing operations with our specialized guide to stamping parts. Designed for our global clientele, this guide offers expert insights, actionable strategies, and practical tips to guarantee your components achieve superior quality and performance. Explore a wealth of knowledge crafted to equip you with the resources and understanding necessary to make informed decisions, enhancing the productivity and efficiency of your manufacturing efforts.

Table of Content

- 1. The Definition of Stamping Parts

- 2. The Stamping Process

- 3. Types of Tolerances in Stamping Parts

- 4. Factors Influencing Tolerances in Stamping

- 5. The Value Proposition of Stamping Parts

- 6. Key Factors in Determining the Cost of Stamping Parts

- 7. Scrap Rate and Its Impact on Stamping Costs

- 8. Maintenance of Stamping Tooling and Dies

- 9. Signs That Mold Needs Immediate Maintenance

1. What Are Stamping Parts?

Stamping parts are critical components in modern manufacturing, created through a process that transforms flat metal sheets into precise shapes and structures. This transformation is achieved using a combination of high-pressure stamping presses and custom-designed dies, which shape the metal into the desired form. The parts produced through stamping can range from simple, flat pieces to complex geometries with multiple bends, cutouts, and intricate details. These parts are essential in various industries, serving as the backbone of countless products we rely on every day.

The Versatility of Stamping Parts: Stamping parts are incredibly versatile, accommodating a wide range of shapes, sizes, and materials. The process can be used to produce everything from small electronic components, like connectors and switches, to large automotive body panels and structural supports. The ability to create such a broad spectrum of parts from different metals, including steel, aluminum, copper, and various alloys, underscores the flexibility of the stamping process. Whether a project requires lightweight components for aerospace applications or robust parts for industrial machinery, stamping can deliver.

Precision and Repeatability: One of the standout features of stamping parts is the precision with which they can be produced. The stamping process allows for tight tolerances, ensuring that each part is made to exact specifications. This precision is crucial in industries where even minor deviations can lead to significant issues, such as in automotive or aerospace manufacturing. Moreover, the stamping process offers high repeatability, meaning that each part produced in a production run is virtually identical. This consistency is vital for manufacturers who need to produce large quantities of parts without sacrificing quality.

2. The Stamping Process: How It Works

Stamping is a manufacturing process that uses a die and a press to convert flat metal sheets into specific shapes. This process is integral to producing a wide variety of parts, from simple to complex designs, with high precision and repeatability. The efficiency and scalability of stamping make it an essential process in industries like automotive, aerospace, electronics, and consumer goods. This chapter delves into each stage of the stamping process, explaining how it works and why it’s a preferred method for producing metal parts.

Stage 1: Blanking

Blanking is the first stage in the stamping process where a flat sheet of metal is cut into a rough shape that will eventually be refined into the final part. The blanking process involves a punch and die, which precisely cut the material to the desired outline. The quality of the blank is crucial as it sets the foundation for all subsequent processes. A poorly cut blank can lead to defects in the final product, making it essential to use high-quality tools and precise control during this stage.

Technical Considerations:

- Material Selection: The choice of material for the blank is critical. Different metals have unique properties, such as hardness and ductility, that affect how they can be blanked.

- Tooling Precision: The punch and die must be meticulously designed and maintained to ensure that the blanking process produces parts that meet the exact specifications.

- Efficiency: Blanking is a high-speed operation, making it ideal for large-scale production. The ability to produce consistent blanks quickly reduces costs and increases throughput.

Stage 2: Punching

Punching is a process that removes material from the blank, creating holes or cutouts as specified by the design. This stage is crucial for parts that require apertures for fastening, ventilation, or integration with other components. The punching process must be carefully controlled to prevent defects such as burrs, which can affect the part’s functionality and aesthetic.

Technical Considerations:

- Precision Punching: The accuracy of the punch and die alignment is vital to ensure clean cuts and minimize material deformation. Advanced machinery equipped with sensors can help maintain this precision.

- Tool Wear: Punching tools are subjected to significant stress, leading to wear over time. Regular maintenance and inspection are necessary to keep the tools in optimal condition and ensure consistent quality.

- Material Waste: Efficient punching minimizes waste by maximizing material utilization. Optimizing the layout of parts on the metal sheet can significantly reduce scrap, lowering overall production costs.

Stage 3: Bending

Bending involves deforming the metal blank to create angles or curves, shaping it closer to its final form. This process is essential for producing parts that require specific geometric profiles, such as brackets, frames, and enclosures. Bending must be performed with high precision to ensure that the angles and dimensions meet the design specifications, which is especially critical in applications where the parts must fit together with other components.

Technical Considerations:

- Material Behavior: Different metals react differently to bending forces. For example, aluminum may require a different approach than steel due to its lower ductility. Understanding material behavior is key to achieving precise bends without cracking or other defects.

- Springback: After bending, some materials tend to spring back slightly, altering the final angle. This must be anticipated and compensated for during the bending process to ensure accuracy.

- Tooling Design: The design of the bending tools, including the punch and die, must match the required bend radius and angle. Complex parts may require custom tooling to achieve the desired shapes.

Stage 4: Forming

Forming is the stage where the part is given its final shape. This process can involve multiple operations, such as drawing (where the metal is stretched into a shape), coining (where specific features are impressed into the part), and embossing (where patterns or textures are added). Forming is often the most complex stage, requiring precise control to produce parts that meet exact specifications.

Technical Considerations:

- Deep Drawing: For parts that require significant depth, deep drawing is used to stretch the metal. This process demands careful control to avoid defects like tearing or wrinkling.

- Complex Geometries: Parts with intricate shapes may require multiple forming operations or the use of progressive dies, where the part is gradually shaped through a series of stages.

- Material Flow: During forming, the material must flow smoothly into the die to fill all features without thinning or breaking. Understanding the material’s flow characteristics is essential to achieving a high-quality part.

Stage 5: Finishing Operations

After the part has been formed, it often requires finishing operations to improve its appearance, performance, and durability. These operations can include trimming excess material, deburring edges, heat treating to enhance strength, and applying surface coatings for protection against corrosion.

Technical Considerations:

- Trimming and Deburring: Ensuring that all excess material is removed and that the edges are smooth is crucial for both safety and functionality. Sharp edges can cause injury or damage when assembling parts.

- Heat Treatment: Some materials require heat treatment to reach their final mechanical properties, such as increased hardness or ductility. The heat treatment process must be carefully controlled to avoid altering the part’s dimensions or causing warping.

- Surface Finishing: Applying coatings, such as paint, powder coating, or galvanization, can protect the part from environmental factors and improve its aesthetic appeal. The choice of finish depends on the part’s intended use and environmental exposure.

Conclusion: The Strategic Advantage of the Stamping Process

The stamping process offers a unique combination of precision, efficiency, and scalability, making it a strategic advantage for manufacturers. Whether producing high-volume parts for the automotive industry or complex components for aerospace applications, stamping provides the versatility and reliability needed to meet diverse market demands.

3. Types of Tolerances in Stamping Parts

Tolerances in stamping parts refer to the permissible variations in a part’s dimensions or physical properties that occur during the manufacturing process. These variations, although often minute, are critical because they determine whether a part will fit and function as intended in its final application. Achieving the correct tolerances is essential for ensuring the quality, reliability, and performance of stamped parts, especially in industries where precision is paramount, such as automotive, aerospace, electronics, and medical devices.

Tolerances are important because even small deviations from the specified dimensions can lead to significant issues down the line. For example, in the automotive industry, a part that is slightly out of tolerance might not fit correctly, leading to assembly problems, increased wear, or even mechanical failure. In electronics, where components often need to fit within tight spaces, improper tolerances can result in malfunctioning devices or poor electrical connections. Therefore, understanding and controlling tolerances is crucial for manufacturers who aim to produce high-quality, reliable parts.

3.1 Dimensional Tolerances

Dimensional tolerances refer to the allowable variation in the physical dimensions of a stamped part, such as length, width, height, and thickness. These tolerances are usually specified in the engineering drawings and are critical for ensuring that the part will fit within its designated space and interact correctly with other components.

Key Considerations:

- Material Characteristics: Different materials react differently to the stamping process. For instance, softer metals like aluminum may be more prone to dimensional changes during stamping, while harder metals like steel may hold dimensions more consistently.

- Tooling Precision: The design and maintenance of the stamping dies directly impact the dimensional accuracy of the parts. Worn or misaligned tooling can lead to parts that are out of tolerance.

- Process Control: Controlling the stamping process, including factors like press speed, pressure, and material handling, is essential to maintaining tight dimensional tolerances.

Applications: Dimensional tolerances are crucial in industries like automotive and aerospace, where parts often need to fit together with other components to form complex assemblies. For example, in automotive applications, a stamped part with tight dimensional tolerances might be used in the engine or transmission, where precision is essential for proper functioning.

3.2 Angular Tolerances

Angular tolerances specify the allowable deviation in the angles of a stamped part. These tolerances are particularly important in parts that have bends or folds, where the exact angle is critical for the part to fit or function correctly. Angular tolerances ensure that parts meet the precise geometric requirements necessary for proper assembly and operation.

Key Considerations:

- Bending Process: The bending stage in stamping is where angular tolerances are most relevant. Factors like material springback, which occurs when the material slightly returns to its original shape after bending, must be accounted for to achieve the desired angle.

- Tool Design: The design of the bending tools, including the punch and die, must be precise to achieve the correct angles. Advanced simulations and careful tool calibration are often used to predict and control angular tolerances.

- Material Thickness: Thicker materials can present more challenges in maintaining angular tolerances due to increased resistance to bending and greater springback.

Applications: Angular tolerances are critical in applications where parts need to form a specific shape or fit within an assembly with precise angles. In construction, for example, structural brackets or support beams must meet stringent angular tolerances to ensure the stability and integrity of the structure.

3.3 Flatness Tolerances

Flatness tolerance refers to the permissible variation in the flatness of a part’s surface. It is a critical factor in parts that must lie flat or mate with other flat surfaces to ensure proper function. Flatness tolerances are essential in avoiding issues such as gaps, uneven wear, or improper assembly.

Key Considerations:

- Material Properties: Certain materials may warp or distort more than others during the stamping process, affecting flatness. For example, materials with higher internal stresses may be more prone to warping.

- Tooling Design: The design and condition of the dies play a significant role in controlling flatness. Dies that are not perfectly flat themselves or are worn can introduce flatness variations in the stamped parts.

- Process Parameters: The stamping process parameters, including press force and speed, must be carefully controlled to minimize any factors that could lead to warping or distortion.

Applications: Flatness tolerances are particularly important in applications like electronics, where components often need to sit flat against circuit boards or other surfaces. In these applications, even a slight variation in flatness can lead to improper connections or component failure.

3.4 Profile Tolerances

Profile tolerance refers to the allowable variation in a part’s surface profile, which is the three-dimensional contour of a surface. This type of tolerance is crucial for parts with complex shapes or surfaces that must interface with other components in a precise manner.

Key Considerations:

- Surface Complexity: Parts with intricate or non-uniform surfaces, such as those with curves or multiple features, require careful control of profile tolerances to ensure all features are produced accurately.

- Tooling and Process Control: Achieving tight profile tolerances requires precision in both tooling and process control. Advanced CNC machining and die design technologies are often employed to maintain these tolerances.

- Material Behavior: The way a material deforms during stamping can affect its final profile. Understanding the material’s flow characteristics and how it reacts under pressure is essential for maintaining the correct profile tolerance.

Applications: Profile tolerances are vital in industries like aerospace and automotive, where parts often have complex geometries that must fit precisely with other components. For example, in the aerospace industry, turbine blades and other aerodynamic components require exact profile tolerances to ensure optimal performance.

3.5 Positional Tolerances

Positional tolerance refers to the allowable deviation in the location of features such as holes, slots, or other specific elements on a stamped part. This type of tolerance is critical for ensuring that these features align correctly with corresponding features on other parts during assembly.

Key Considerations:

- Tooling Accuracy: The position of features like holes is directly related to the accuracy of the die and punch. Any misalignment in the tooling can lead to positional errors.

- Process Stability: Ensuring that the stamping process remains stable over long production runs is essential for maintaining positional tolerances. Variations in material feed or press performance can affect the accuracy of feature placement.

- Inspection and Quality Control: Advanced measurement techniques, such as coordinate measuring machines (CMMs), are often used to verify that features meet the specified positional tolerances.

Applications: Positional tolerances are crucial in assemblies where multiple parts must fit together with precise alignment. In automotive manufacturing, for example, components such as engine mounts or suspension parts must have holes and slots that align perfectly with other parts for proper assembly and operation.

3.6 Runout Tolerances

Runout tolerance is a measure of how much a surface or feature deviates from its intended rotational axis. It is particularly important in parts that rotate or are subject to rotational motion, where even slight deviations can cause vibration, noise, or mechanical failure.

Key Considerations:

- Material Selection: The choice of material can affect runout tolerance, particularly in parts that are prone to deformation under rotational stress.

- Tooling and Machining: Achieving tight runout tolerances requires precision machining and tooling, especially for parts like shafts, gears, and other rotational components.

- Inspection Techniques: Runout is often measured using specialized equipment such as dial indicators or laser measurement systems, ensuring that the parts meet the required tolerances.

Applications: Runout tolerances are critical in applications where parts rotate at high speeds, such as in automotive engines, electric motors, and aerospace components. Ensuring minimal runout helps to maintain smooth operation and prolongs the life of the parts.

Conclusion: The Critical Role of Tolerances in Stamping Parts

Tolerances are a fundamental aspect of the stamping process, defining the boundaries within which a part must be manufactured to ensure it performs as intended. Understanding the different types of tolerances—dimensional, angular, flatness, profile, positional, and runout—allows manufacturers to produce parts that not only meet but exceed the stringent requirements of various industries. By maintaining tight control over these tolerances, you can ensure that your stamping parts are of the highest quality, offering reliability, durability, and precise fit in every application.

4. Factors Influencing Tolerances in Stamping

Tolerances in stamping are critical for ensuring that parts meet the exact specifications required for their intended applications. Achieving and maintaining these tolerances involves careful control of various factors throughout the stamping process. Understanding these factors is crucial for manufacturers who aim to produce high-quality parts with consistent precision. In this chapter, we will explore the key factors that influence tolerances in stamping and discuss how they can be managed to ensure optimal outcomes.

4.1 Material Properties

Material Composition: The composition of the material being stamped plays a significant role in determining how well tolerances can be maintained. Different metals and alloys exhibit varying degrees of ductility, hardness, and strength, which affect how they behave during the stamping process. For example, high-strength steels are often more challenging to stamp accurately due to their resistance to deformation, which can lead to springback and other tolerance issues. Conversely, softer metals like aluminum may be easier to form but can be prone to dimensional changes during stamping.

Material Thickness: The thickness of the material also has a profound impact on tolerances. Thicker materials require more force to shape, which can lead to greater tool wear and potential deviations in the final part dimensions. On the other hand, thinner materials may be more susceptible to issues like warping or tearing if not handled correctly. Manufacturers must carefully select the appropriate material thickness based on the design requirements and desired tolerances.

Grain Structure: The grain structure of the metal can influence its formability and the accuracy of the final dimensions. Metals with a fine, uniform grain structure tend to deform more predictably, allowing for tighter control over tolerances. Conversely, metals with coarse or irregular grain structures may exhibit inconsistent behavior during stamping, leading to variations in the final part dimensions.

Material Hardness: The hardness of the material affects how it interacts with the tooling during stamping. Harder materials may resist deformation, making it more challenging to achieve the desired shapes and dimensions within the specified tolerances. This resistance can also lead to increased tool wear, requiring more frequent maintenance or replacement of the dies.

Managing Material Properties: To manage these material-related factors effectively, manufacturers must carefully select materials that are suited to the specific stamping application and ensure that the material quality is consistent. This involves working closely with material suppliers to ensure that the raw materials meet the required specifications and conducting regular inspections to verify material properties before production begins.

4.2 Tooling Design and Condition

Tooling Precision: The design and precision of the tooling are critical to achieving and maintaining tight tolerances in stamping. The dies used in stamping must be meticulously designed to match the exact specifications of the part. Any deviations in the tooling design can lead to inaccuracies in the final part dimensions. Additionally, the tooling must be manufactured to high precision standards, with tight control over factors such as surface finish, alignment, and hardness.

Tool Wear: Tool wear is a natural consequence of the stamping process, especially when dealing with high-strength materials or large production volumes. As the tooling wears down, it can lead to changes in the dimensions and surface quality of the stamped parts, resulting in deviations from the specified tolerances. Regular inspection and maintenance of the tooling are essential to prevent wear from affecting part quality. In some cases, tooling may need to be refurbished or replaced to maintain the desired tolerances.

Tool Alignment: Proper alignment of the tooling is crucial for ensuring consistent tolerances. Misalignment between the punch and die can cause uneven force distribution during stamping, leading to dimensional variations and potential defects such as burrs or misformed features. Precision alignment tools and techniques are used to ensure that the tooling remains correctly aligned throughout the production run.

Advanced Tooling Materials: The use of advanced tooling materials, such as carbide or tool steels with high wear resistance, can help extend the life of the tooling and maintain tighter tolerances over longer production runs. These materials are designed to withstand the high pressures and abrasive forces involved in stamping, reducing the rate of tool wear and improving overall part quality.

Tooling Maintenance: Implementing a proactive tooling maintenance program is essential for managing the factors that influence tolerances. This includes regular inspection of the tooling for signs of wear, proper lubrication to reduce friction and wear, and timely replacement or refurbishment of worn tools. By maintaining the tooling in optimal condition, manufacturers can ensure that tolerances are consistently met throughout the production process.

4.3 Stamping Process Control

Press Force and Speed: The force and speed at which the stamping press operates are critical factors that influence tolerances. If the press force is too high, it can cause the material to deform beyond the desired dimensions, leading to out-of-tolerance parts. Conversely, if the force is too low, the material may not fully form to the die, resulting in incomplete or undersized parts. The speed of the press also plays a role, as faster speeds can increase the risk of material springback or other deformation issues. Precise control over press force and speed is essential for maintaining the desired tolerances.

Temperature and Environmental Conditions: Environmental factors, such as temperature and humidity, can affect the stamping process and the resulting tolerances. Metals expand and contract with changes in temperature, which can influence the dimensions of the stamped parts. High temperatures can also affect the properties of the tooling, potentially leading to increased wear or changes in alignment. Manufacturers must monitor and control the production environment to minimize the impact of these factors on tolerances.

Material Handling: The way materials are handled before and during the stamping process can significantly impact tolerances. Improper handling, such as bending or scratching the material, can introduce defects that affect the final dimensions of the part. Additionally, inconsistencies in material feeding, such as variations in the speed or alignment of the material as it enters the press, can lead to tolerance issues. Automated material handling systems, combined with regular inspections, can help ensure consistent material feeding and minimize the risk of handling-related defects.

Process Stability: Maintaining a stable stamping process is essential for achieving consistent tolerances. This involves closely monitoring the performance of the press, tooling, and material handling systems to identify and address any issues that could lead to variations in part dimensions. Advanced process control systems, such as real-time monitoring and feedback loops, can help maintain stability and ensure that tolerances are consistently met.

In-Process Inspection: In-process inspection is a critical component of process control. By inspecting parts during the stamping process, manufacturers can quickly identify and correct any issues that could lead to out-of-tolerance parts. This proactive approach helps minimize waste and rework while ensuring that the final parts meet the required specifications. Common in-process inspection techniques include optical measurement systems, coordinate measuring machines (CMMs), and laser scanning.

4.4 Part Design Complexity

Complex Geometries: The complexity of the part design can have a significant impact on the ability to maintain tight tolerances. Parts with intricate geometries, such as multiple bends, deep draws, or fine details, present more challenges in controlling tolerances. The more complex the design, the greater the potential for variations in the final dimensions due to factors such as material flow, springback, and tooling interaction.

Feature Interactions: When a part design includes multiple features that interact with each other, such as holes, slots, and bends, maintaining tolerances becomes more challenging. Each feature can influence the others, leading to cumulative tolerance variations that can affect the overall fit and function of the part. Manufacturers must carefully consider the interactions between features during the design and tooling stages to ensure that tolerances are maintained.

Progressive Die Stamping: For parts with complex designs, progressive die stamping is often used to achieve the desired shape through a series of sequential operations. Each stage of the progressive die introduces new features or refines existing ones, making it essential to control tolerances at every step. Any deviation in one stage can affect the subsequent stages, leading to cumulative errors that impact the final part dimensions.

Simulation and Testing: To manage the challenges of complex part designs, manufacturers often use advanced simulation software to predict how the material will behave during stamping. These simulations can help identify potential tolerance issues before production begins, allowing for adjustments to the design, tooling, or process parameters. Additionally, prototype testing is used to validate the design and ensure that the parts meet the required tolerances.

Summary: The Importance of Managing Tolerance Influencing Factors

Achieving and maintaining tight tolerances in stamping parts is a complex task that requires careful control over a variety of factors. Material properties, tooling design and condition, process control, and part design complexity all play critical roles in determining the final part dimensions.

5. The Value Proposition of Stamping Parts

In today’s competitive manufacturing landscape, the ability to produce high-quality components efficiently and cost-effectively is crucial for success. Stamping parts offer a unique value proposition that makes them indispensable across various industries, including automotive, aerospace, electronics, and consumer goods. The value of stamping parts is derived from several key attributes, including their precision, durability, cost-effectiveness, and versatility. This chapter delves into these attributes, providing a detailed exploration of why stamping parts are often the preferred choice for manufacturers looking to optimize their production processes and product performance.

5.1 Precision and Consistency

Achieving Tight Tolerances: One of the most significant advantages of stamping parts is the ability to achieve tight tolerances with remarkable consistency. The precision of the stamping process ensures that each part is produced to exact specifications, meeting the stringent requirements of industries where even the smallest deviation can lead to functional failures or assembly issues. This level of precision is particularly critical in applications such as automotive safety components, aerospace structures, and electronic connectors, where reliability and performance are non-negotiable.

Consistency in Mass Production: Stamping is inherently a high-repeatability process, meaning that the first part off the press is virtually identical to the last, even in large production runs. This consistency is a key value driver for manufacturers who need to produce thousands or even millions of parts with uniform quality. Consistency not only enhances the reliability of the end product but also simplifies assembly processes, reduces the need for quality inspections, and minimizes the risk of defects that could lead to costly recalls or rework.

Leveraging Advanced Technology: Modern stamping processes leverage advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and real-time process monitoring to achieve and maintain precision. These technologies allow for the precise control of every aspect of the stamping process, from tool design to material handling, ensuring that parts are produced to the highest standards of accuracy. By investing in these technologies, manufacturers can further enhance the precision and consistency of their stamping operations, delivering superior value to their customers.

5.2 Durability and Strength

Material Integrity: Stamping parts are known for their durability and strength, attributes that are critical for components subjected to high stress, wear, and environmental challenges. The stamping process itself contributes to the strength of the parts, as it involves cold working the metal, which can increase its hardness and resistance to deformation. This makes stamped parts particularly well-suited for demanding applications in the automotive, aerospace, and industrial machinery sectors, where parts must withstand rigorous operating conditions.

Structural Integrity: The inherent structural integrity of stamped parts is another key aspect of their value proposition. Because stamping creates parts from a single piece of material, without the need for joints or welds, the resulting components are often stronger and more resistant to failure than those produced by other manufacturing methods. This is especially important in safety-critical applications, such as automotive crash components or aerospace structural elements, where part failure is not an option.

Corrosion Resistance and Longevity: Many stamped parts are designed to offer excellent corrosion resistance, which is essential for applications exposed to harsh environments, such as automotive undercarriages or outdoor electrical enclosures. By selecting appropriate materials, such as stainless steel or coated metals, manufacturers can produce stamped parts that not only meet the required strength and durability standards but also provide long-term resistance to corrosion, ensuring a longer service life.

5.3 Cost-Effectiveness

Economies of Scale: One of the most compelling aspects of the value proposition of stamping parts is their cost-effectiveness, particularly in large production volumes. Once the initial tooling is created, the cost per part decreases significantly as production scales up. This makes stamping an ideal choice for mass production, where manufacturers can achieve substantial cost savings while maintaining high levels of quality. The ability to produce large quantities of parts at a low cost per unit is a key competitive advantage for manufacturers in industries like automotive and consumer electronics, where price pressures are intense.

Tooling Investment and Long-Term Savings: While the initial investment in stamping tooling can be substantial, this cost is typically offset by the long-term savings achieved through high-volume production. High-quality stamping dies are designed for longevity, capable of producing hundreds of thousands or even millions of parts with minimal wear. This durability means that the tooling costs are amortized over a large number of parts, reducing the overall cost per unit and making stamping a cost-effective solution for long production runs.

Material Efficiency: Stamping is also a highly material-efficient process, which further contributes to its cost-effectiveness. The process is designed to minimize waste by optimizing the layout of parts on the metal sheet and by recycling scrap material. This efficiency not only reduces material costs but also aligns with sustainability goals, making stamping an environmentally responsible choice for manufacturers looking to minimize their ecological footprint.

5.4 Versatility and Flexibility

Wide Range of Applications: The versatility of stamping parts is a significant component of their value proposition. Stamping can be used to produce a vast array of parts across different industries, from simple washers and brackets to complex automotive panels and electronic enclosures. The ability to produce parts of varying sizes, shapes, and complexities makes stamping an incredibly flexible manufacturing process that can be adapted to meet the specific needs of virtually any application.

Material Versatility: Stamping can be performed on a wide range of materials, including steel, aluminum, copper, and specialty alloys. This material versatility allows manufacturers to choose the best material for the job, whether the priority is strength, weight, corrosion resistance, or conductivity. By offering the flexibility to work with different materials, stamping provides manufacturers with the freedom to design parts that meet the exact requirements of their projects, whether in terms of performance, aesthetics, or cost.

Customization and Innovation: The stamping process also allows for a high degree of customization, enabling manufacturers to produce parts that are tailored to their specific needs. Advanced tooling techniques, such as progressive dies and multi-slide stamping, allow for the creation of complex parts with multiple features in a single operation. This capability not only streamlines the production process but also encourages innovation, as designers can experiment with new shapes and features without being constrained by the limitations of other manufacturing methods.

5.5 Efficiency and Speed

High-Speed Production: One of the standout advantages of stamping is the speed at which parts can be produced. Modern stamping presses are capable of producing hundreds or even thousands of parts per hour, making stamping one of the fastest manufacturing processes available. This high-speed production is particularly beneficial in industries where time-to-market is critical, such as consumer electronics or automotive manufacturing, where rapid product cycles and quick turnarounds are essential for maintaining a competitive edge.

Shorter Lead Times: The efficiency of the stamping process also translates into shorter lead times, allowing manufacturers to respond more quickly to market demands. Whether producing parts for a new product launch or ramping up production to meet increased demand, stamping offers the ability to scale up production rapidly without sacrificing quality. This agility is a key value driver for manufacturers who need to stay ahead in fast-paced industries.

Reduced Labor Costs: The automation inherent in the stamping process reduces the need for manual labor, which not only lowers production costs but also minimizes the potential for human error. By reducing labor-intensive operations and streamlining the production process, stamping allows manufacturers to achieve higher productivity with fewer resources, further enhancing the cost-effectiveness and value of the process.

5.6 Environmental Responsibility

Sustainable Manufacturing: In an era where sustainability is increasingly important, the environmental benefits of stamping add to its value proposition. Stamping is a relatively low-waste process, especially when compared to other manufacturing methods like machining, which can generate significant amounts of material waste. The scrap generated during stamping can often be recycled, reducing the overall environmental impact of the process.

Energy Efficiency: Modern stamping presses are designed to be energy-efficient, consuming less power than other manufacturing methods that require extensive machining or heating processes. This energy efficiency not only reduces operational costs but also contributes to a smaller carbon footprint, making stamping an environmentally responsible choice for manufacturers looking to reduce their impact on the planet.

Supporting Circular Economy: The ability to use recycled materials in the stamping process further supports a circular economy, where resources are reused and waste is minimized. By incorporating recycled metals into their production processes, manufacturers can reduce their reliance on virgin materials, lowering both costs and environmental impact.

Conclusion: Why Stamping Parts Offer Superior Value

The value proposition of stamping parts is multifaceted, encompassing precision, durability, cost-effectiveness, versatility, efficiency, and environmental responsibility. These attributes make stamping parts an ideal choice for manufacturers seeking to produce high-quality components at scale, while also meeting the demands of modern industries that prioritize sustainability, innovation, and speed.

6. Key Factors in Determining the Cost of Stamping Parts

The cost of producing stamping parts is influenced by a variety of factors, each of which plays a critical role in determining the final price. For manufacturers and buyers alike, understanding these factors is essential for making informed decisions, optimizing budgets, and ensuring that the final product meets both performance and cost expectations. This chapter explores the key factors that influence the cost of stamping parts, providing insights into how these elements interact and how they can be managed to achieve the best possible outcomes.

6.1 Material Costs

Material Selection: The choice of material is one of the most significant factors affecting the cost of stamping parts. Different materials come with varying price points, depending on factors such as availability, demand, and processing complexity. For instance, metals like stainless steel and titanium are more expensive than aluminum or mild steel, primarily due to their superior properties, such as strength, corrosion resistance, and durability. The specific application and performance requirements of the part will often dictate the material selection, which in turn influences the overall cost.

Material Grade and Quality: Beyond the basic material type, the grade and quality of the material also impact costs. Higher-grade materials, which offer better mechanical properties or enhanced corrosion resistance, typically come at a premium. Additionally, materials with certifications or compliance with industry standards (such as automotive or aerospace specifications) can be more expensive due to the rigorous testing and quality assurance processes involved.

Material Thickness and Size: The thickness and size of the material used in stamping also affect the cost. Thicker materials require more force and more robust tooling, which can increase both material and production costs. Larger blanks or coils, necessary for producing bigger parts, also lead to higher material costs. Manufacturers must carefully balance material thickness and size with the performance requirements of the final part to optimize costs without compromising quality.